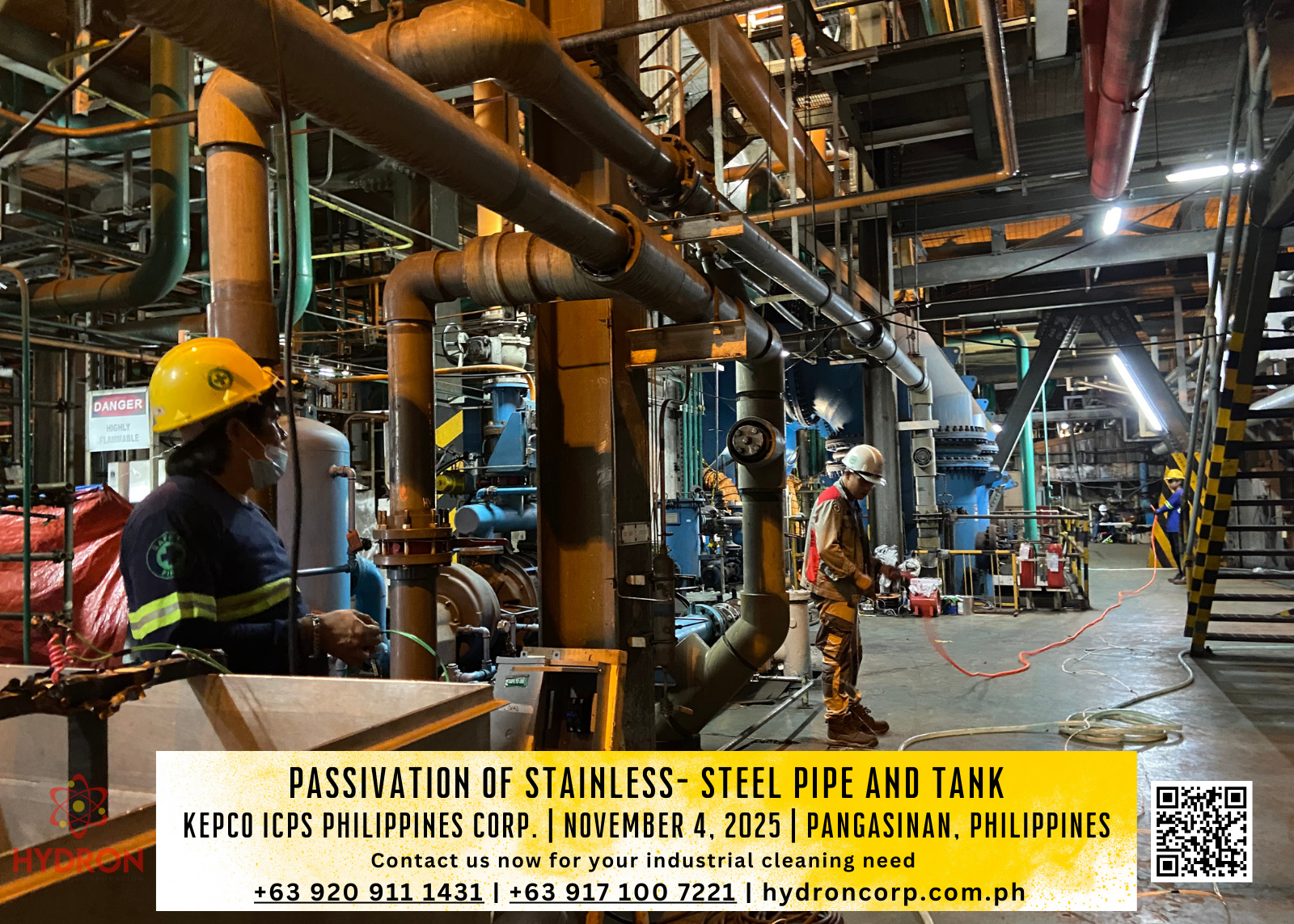

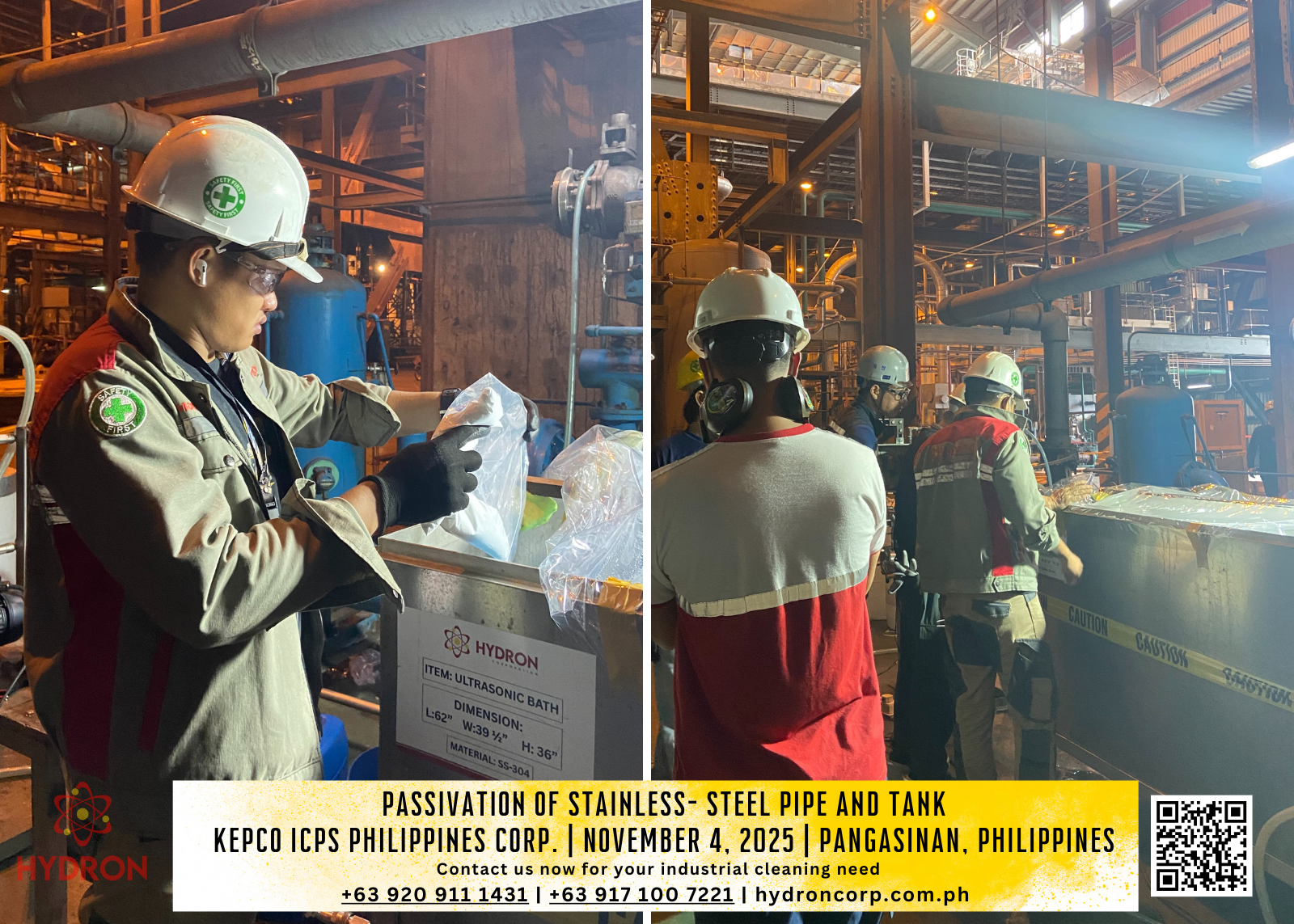

Passivation of Stainless Steel Pipes and Tank

Kepco ICPS Philippines Corp. | November 4, 2025 | Pangasinan Philippines

Passivation is a specialized industrial cleaning and surface treatment process that removes free iron, contaminants, and fabrication residues from stainless steel. We carried out this project to restore and enhance the corrosion resistance of stainless steel surfaces used in critical plant processes.

During installation, welding, or maintenance, stainless steel surfaces can become contaminated with carbon steel particles, oils, or oxides, which weaken the material’s natural protective layer. Passivation chemically restores the chromium-rich oxide layer, allowing stainless steel to resist corrosion, pitting, and premature degradation, which is especially important in humid, coastal, and high-temperature environments typical in the Philippines.

Through this project, the company helped clients extend equipment lifespan, maintain process integrity, and reduce long-term maintenance costs. Properly passivated systems also support compliance with industry standards, ensuring reliable and efficient operations in demanding industrial environments.

REQUEST A QUOTE

- • PASSIVATION

- • PIPELINE CHEMICAL CLEANING of POWERPLANTS

- • DESCALING of BOILERS and HEAT EXCHANGERS

- • CHEMICAL CLEANING (ACID/ALKALI APPLICATION)

- • CONDENSER TUBES CHEMICAL CLEANING

- • POTABLE WATER TANK CLEANING and DISINFECTION

- • PIPELINES DECLOGGING

- • FLOOR and EQUIPMENT DEGREASING

- • CLEANING of COOLING TOWERS

- • PRE-OPERATION PIPELINE CHEMICAL CLEANING and FLUSHING (PASSIVATION)

- • RUST REMOVAL and ANTI-RUST COATING APPLICATION

- • CLEANING of SHIPS ENGINE AIR COOLER

- • WATER TREATMENT, MONITORING, and DOSIN

- If you are interested in our industrial cleaning services or have any questions, please click contact us. We are always at your service.