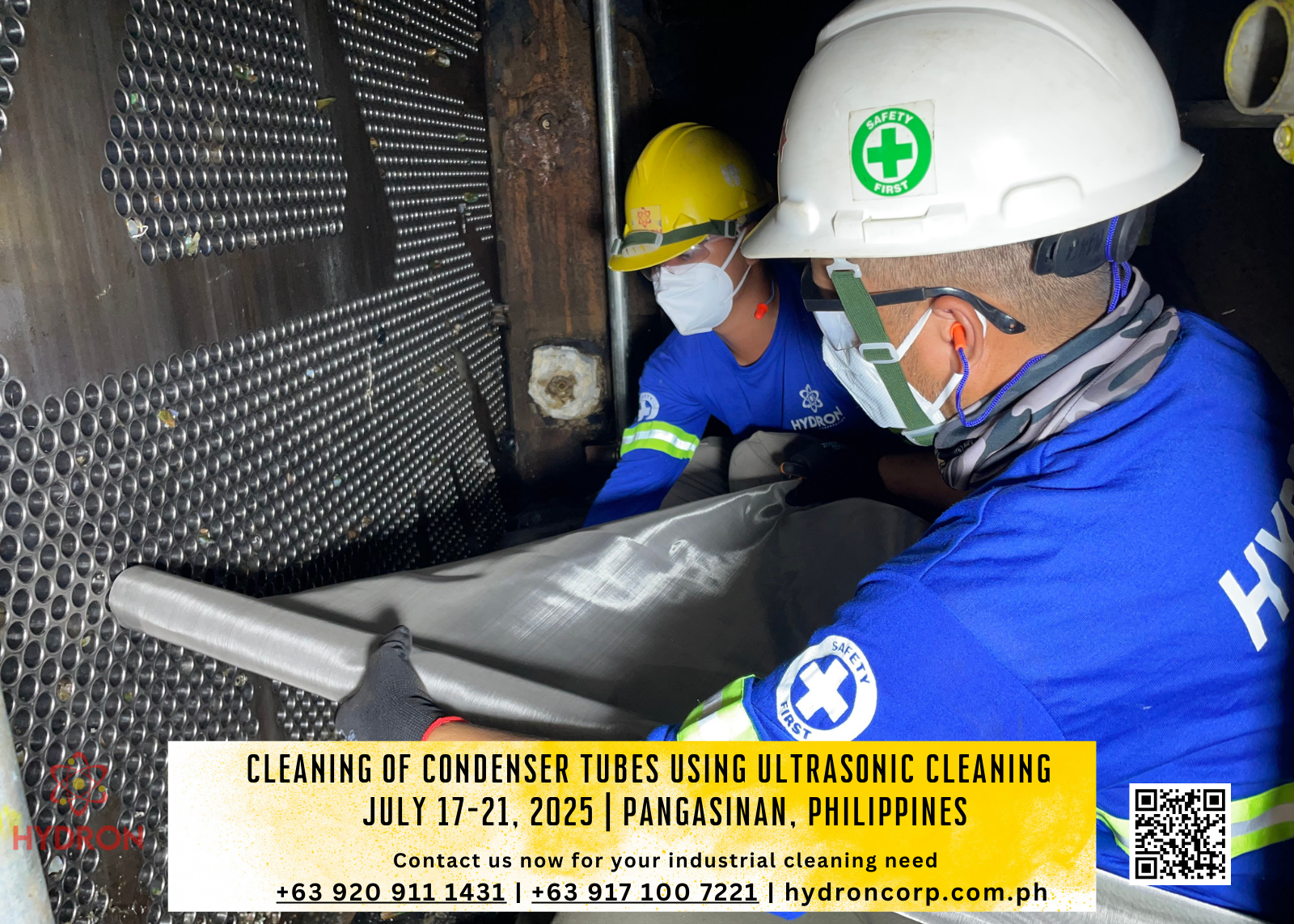

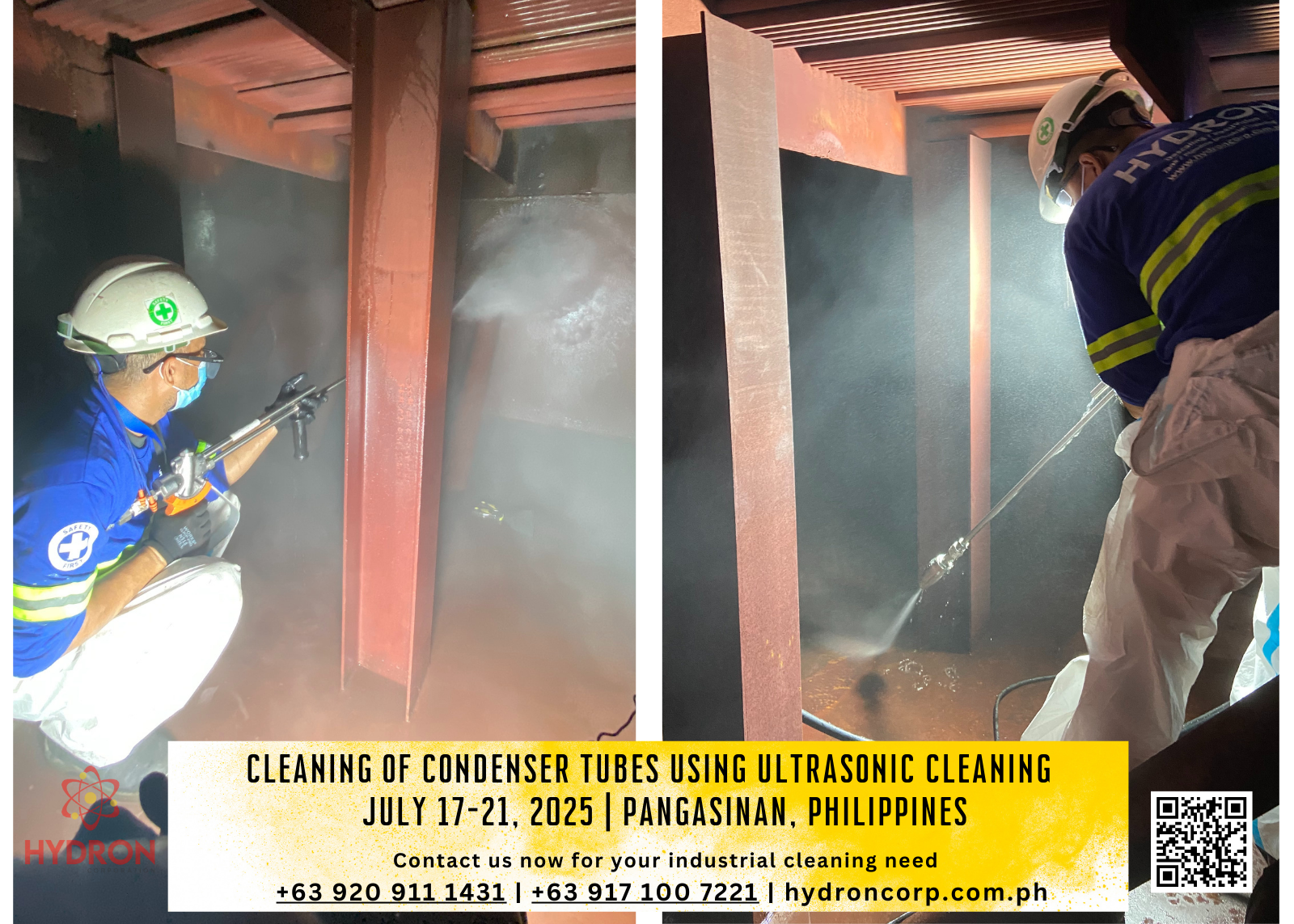

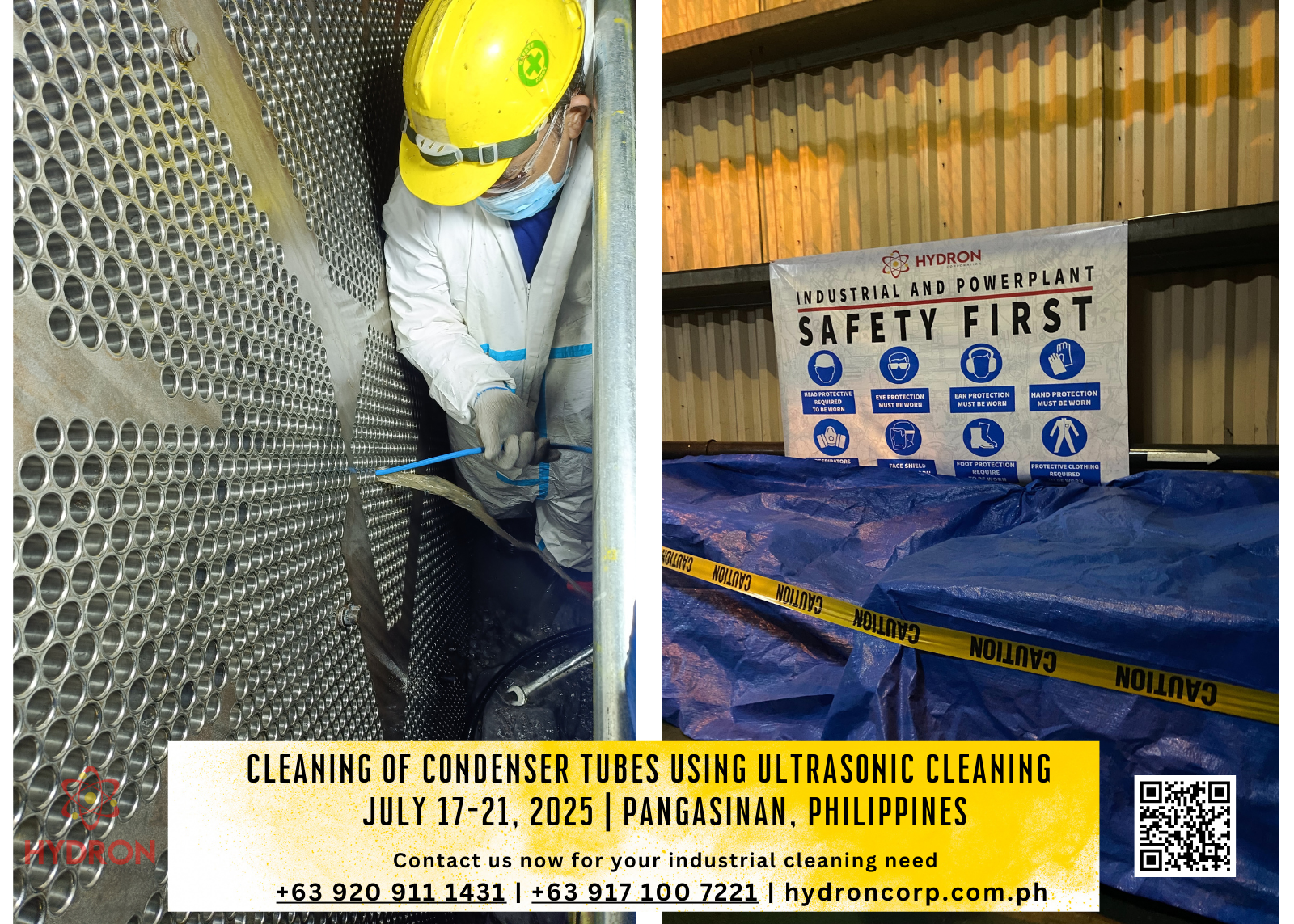

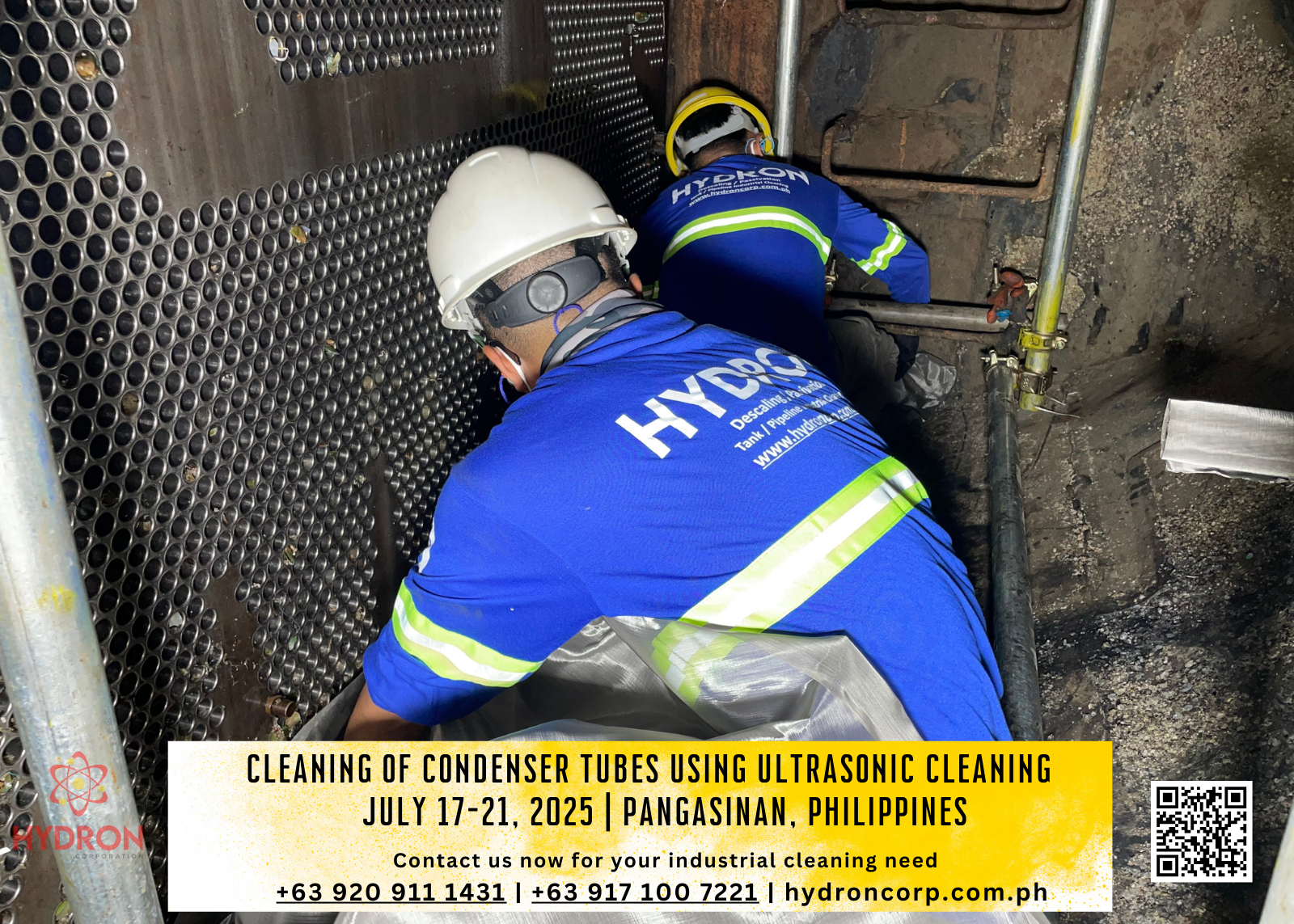

Ultrasonic Condenser Tube Cleaning

July 17-21, 2025 | Pangasinan, Philippines

We completed multiple ultrasonic condenser tube cleaning projects using ultrasonic cleaning technology for one of the industrial and power generation facilities in the Philippines. This project focused on restoring heat-transfer efficiency and improving overall system performance without damaging critical condenser components.

Fouled condenser tubes lead to higher energy consumption, reduced cooling efficiency, increased operating temperatures, and potential equipment failure. In severe cases, poor heat transfer can cause forced outages and costly downtime. Ultrasonic cleaning provides a non-destructive solution that extends tube life while restoring optimal thermal performance.

In the Philippines’ warm climate, where cooling efficiency is critical, ultrasonic condenser tube cleaning supports stable plant operations, improved output, and long-term equipment protection.

REQUEST A QUOTE

- • PASSIVATION

- • PIPELINE CHEMICAL CLEANING of POWERPLANTS

- • DESCALING of BOILERS and HEAT EXCHANGERS

- • CHEMICAL CLEANING (ACID/ALKALI APPLICATION)

- • CONDENSER TUBES CHEMICAL CLEANING

- • POTABLE WATER TANK CLEANING and DISINFECTION

- • PIPELINES DECLOGGING

- • FLOOR and EQUIPMENT DEGREASING

- • CLEANING of COOLING TOWERS

- • PRE-OPERATION PIPELINE CHEMICAL CLEANING and FLUSHING (PASSIVATION)

- • RUST REMOVAL and ANTI-RUST COATING APPLICATION

- • CLEANING of SHIPS ENGINE AIR COOLER

- • WATER TREATMENT, MONITORING, and DOSIN

- If you are interested in our industrial cleaning services or have any questions, please click contact us. We are always at your service.