How Important is pH Balance in the Passivation Process?

Passivation is a critical process in ensuring stainless steel’s longevity and corrosion resistance, and maintaining the proper pH level during passivation is one of the critical factors in the passivation process.

But before delving into pH balance, we must grasp passivation’s fundamentals. Passivation is a chemical process designed to enhance the corrosion resistance of stainless steel. This is achieved by removing contaminants from the surface of the steel and creating a passive oxide layer.

The passive oxide layer, primarily chromium oxide, acts as a protective shield against corrosion. This layer grants stainless steel its renowned durability and resistance to environmental elements. Maintaining the proper pH balance is crucial to optimize the formation of this protective layer. The process typically involves the use of an acid-based solution, and the pH of this solution determines its acidity.

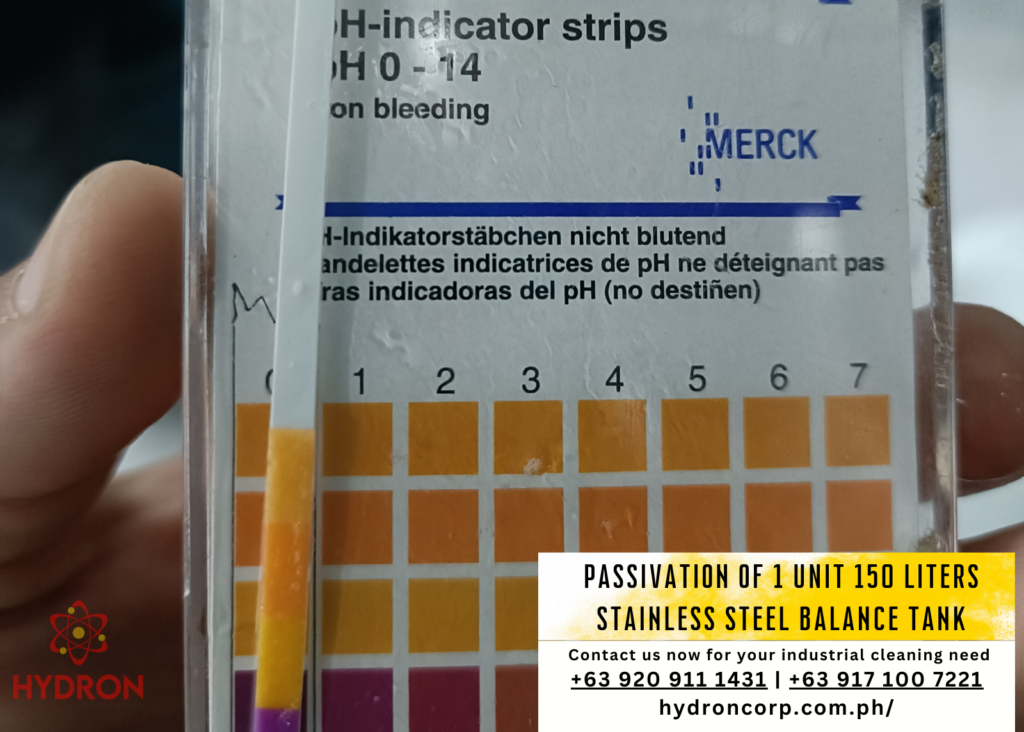

The pH scale is a common measure used to determine the acidity or alkalinity of a given solution. The concentration of hydrogen ions in it determines a solution’s pH level. It provides valuable insight into the chemical properties and reactivity of the solution. The term pH itself stands for the potential of hydrogen, and it is an important concept in fields ranging from chemistry to environmental science. By understanding pH, we can better understand and manipulate the properties of various solutions.

Optimal pH Range for Passivation:

The passivation process is most effective within a specific pH range. Typically, a mildly acidic solution with a pH between 1.5 and 3.5 is employed for passivating stainless steel. This acidity is essential for removing iron and other contaminants from the surface, allowing the formation of the protective chromium oxide layer.

What are the effects of Low pH (Acidity):

- Low pH levels enhance the dissolution of iron and other contaminants from the stainless steel surface. This is a crucial step in preparing the surface for forming the passive oxide layer.

- The acidic environment facilitates the initiation of the passivation process, leading to the creation of the protective chromium oxide layer. This layer is imperative for safeguarding the stainless steel against corrosion.

- The acidic nature of the solution accelerates the chemical reactions involved in passivation, resulting in a more efficient and time-effective process.

How about the effects of High pH (Alkalinity):

- A solution with high pH levels may slow down the dissolution of contaminants, hindering the effective removal of impurities from the stainless steel surface.

- High alkalinity can impede passivation, leading to less effective oxide layer formation. This compromises the corrosion resistance of the stainless steel.

Ensuring Precision in pH Control:

Alkaline solutions may leave residues on the surface, affecting the overall passivation quality. Residues can interfere with the protective oxide layer and compromise its integrity.

The effectiveness of passivation is intricately tied to the Precision in controlling pH levels. Regular monitoring and adjustment of the passivating solution’s pH are essential to maintain the optimal conditions for passivation.

To efficiently remove contaminants, accelerate the formation of the protective oxide layer, and fortify stainless steel against corrosion, striking the correct pH balance is crucial in stainless steel passivation.

Industries highly value stainless steel for its exceptional durability and attractive appearance. Hence, it is crucial to maintain meticulous control over pH during the passivation process. By comprehending the impact of pH on passivation, industries can enhance their approach towards stainless steel maintenance. This will ultimately aid in preserving the steel’s integrity and prolonging its longevity, protecting it from corrosive challenges.

Schedule your passivation service today and learn more about how the proper passivation process impacts your industry. Contact us to explore customized industrial cleaning solutions tailored to your business needs. Call us at +63 920 911 1431 | +63 917 100 7221