The Comprehensive Process of Cleaning Your Water Tank

Tank cleaning is a critical maintenance process that involves the removal of debris, contaminants, and residues from storage tanks to ensure proper functionality, safety, and product quality. This comprehensive process requires meticulous planning, thorough execution, and adherence to industry best practices. In this article, we will explore the step-by-step process of tank cleaning, highlighting its importance in maintaining operational efficiency and preventing potential hazards.

Preparation for Cleaning of Tank

The initial step in the tank cleaning process involves thorough preparation to ensure a safe and effective operation. The preparation includes gathering the necessary tools and equipment, assessing the tank’s condition, and implementing safety measures. Personnel involved in the cleaning process should wear appropriate protective gear and follow established safety protocols.

Scraping the White Debris and Collecting the Debris

Once the tank is properly prepared, the next step is removing any loose debris or sediment on the tank’s interior surfaces. This is done using brushes and shovels, carefully scraping and collecting the white debris, such as scale or sediment, that may have accumulated over time.

After the debris is scraped, it must be collected and removed from the tank. It is important to ensure proper disposal of the accumulated debris, adhering to environmental regulations and guidelines.

Preparation for Water Flushing and Ventilation

Water flushing is a crucial step in the tank cleaning process. Before initiating the flushing, the tank needs to be properly prepared. This involves closing off any external connections, such as inlet and outlet valves, to prevent the inflow and outflow of water during the flushing process.

Proper ventilation is essential to maintain a safe working environment during tank cleaning. Adequate ventilation ensures the removal of potentially harmful gases, fumes, or vapors that may be present inside the tank. Ventilation equipment, such as fans or blowers, should be used to facilitate the airflow.

Water Flushing and Degreasing

Water flushing removes residual debris, sediments, and contaminants from the tank’s interior. High-pressure water jets or hoses are utilized to flush the tank thoroughly, and to ensure a comprehensive cleaning, the water is directed towards all tank areas, including corners, seams, and hard-to-reach spots.

In some cases, tanks may accumulate grease or oily residues. Degreasing is necessary to remove such contaminants. Specialized degreasers or cleaning agents are applied to dissolve and dislodge the greasy deposits, ensuring a clean and residue-free tank surface.

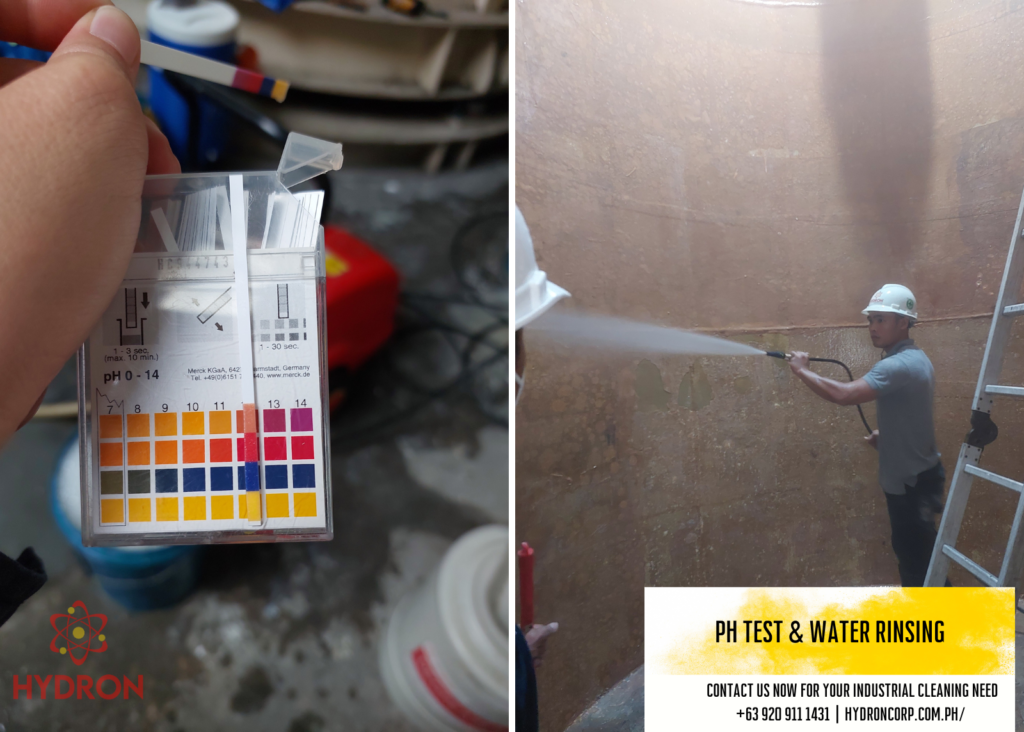

pH Test

Following the water flushing and degreasing, a pH test is conducted to assess the tank’s cleanliness. The pH level of the rinse water is measured, and a pH of 13 is typically considered an indication of sufficient cleaning and removal of contaminants.

Water Rinsing and Draining

After the pH test confirms the cleanliness, the tank is rinsed again with clean water. This step helps remove any residual cleaning agents or chemicals, ensuring the tank is free from potential contaminants.

Once the tank is thoroughly rinsed, the water is drained. Proper drainage procedures should be followed, ensuring the water is discharged safely and according to environmental regulations.

Vacuuming the Tank and Final Rinsing

Tank vacuuming is needed to ensure the complete removal of the remaining moisture. Vacuum equipment extracts water or moisture, leaving the tank surface dry.

In the final step, the tank undergoes a final rinse using clean water to eliminate any remaining traces of debris, cleaning agents, or moisture. This ensures the tank is ready for subsequent use or storage.

The process of tank cleaning holds immense importance for several reasons:

- Operational Efficiency: Regular tank cleaning helps maintain optimal operational efficiency by preventing clogging, blockages, or contamination that can hinder the flow or quality of stored materials.

- Product Quality and Safety: Clean tanks ensure the integrity and quality of stored products, preventing cross-contamination and maintaining product purity. This is crucial in industries such as food and pharmaceuticals.

- Environmental Compliance: Proper tank cleaning practices adhere to environmental regulations, ensuring responsible waste management and minimizing the impact on the surrounding environment.

- Preventing Hazards: Thorough tank cleaning reduces the risk of potential hazards, such as the growth of bacteria, mold, or the accumulation of flammable or explosive materials, safeguarding the health and safety of personnel and the surrounding area.

- Extending Equipment Lifespan: Regular cleaning and maintenance help prolong the lifespan of tanks by preventing corrosion, scaling, or other forms of deterioration that can lead to costly repairs or replacements.

The tank cleaning process involves meticulous planning, thorough execution, and adherence to safety protocols. By following comprehensive steps, industries can ensure operational efficiency, maintain product quality and safety, comply with environmental regulations, prevent hazards, and extend the lifespan of their tanks. Regular tank cleaning is an essential maintenance practice contributing to a safe, efficient, and sustainable industrial operation.